Manufacture of wooden furniture

Making wooden furniture is an activity that we have been engaged in since 2006. As a rule, we use solid wood and plywood as materials, in some individual projects (e.g. making doors) MDF board too. Unfortunately, we do not make furniture from melamine board and laminate board.

We cooperate with reputable furniture manufacturers such as HETTICH, Kessebohmer, Koblenz, Hailo (HETEST OÜ.), Haffele, Blum door lifts (Furnituur AS), TULIP handles.

We finish our products with professional and industrial finishes from Akzo Nobel (KarlBilder OÜ).

Wooden furniture we manufacture

We manufacture the following products according to the special wishes of our customers:

- Kitchen furniture

- Bedroom furniture

- Wardrobe beds

- Wardrobes

- Living room furniture

- Bathroom furniture

- Dining and coffee tables

- TV bases

- Shelves

- and much more

In short, we do not make chairs or interior doors, the rest is all part of our production.

Consulting

We have taken into account that the production of wooden furniture is complicated, so it can be difficult for some of clients to describe their wishes. That is why we are always ready to help with professional advice and strength.

For example: if you feel that drawing is not really your cup of tea, we will visit you and help you design the necessary furniture.

What is the price of wooden furniture?

Although the production of wooden furniture is more expensive than the purchase of cheap furniture, we have so far been able to maintain a reasonable limit in terms of price.

However, you should keep in mind that the price depends primarily on what kind of furniture you need and what material you want to use. Example: Making solid wood kitchen furniture is more expensive than making furniture from ordinary MDF. At the same time, the life cycle of wooden furniture is significantly longer than that of furniture with MDF housing. Thus, wooden furniture is suitable for a green-minded person who appreciates originality, longevity and quality.

What material is wooden furniture made of?

The manufacture of wooden furniture also depends a lot on the material used. In the furniture we manufacture, we use only wood material and wooden tile material (e.g. plywood and joinery board).

Laminate, melamine or MDF boards are not found in our furniture cases (although wood is actually used as the starting material in artificial boards (laminate and MDF).

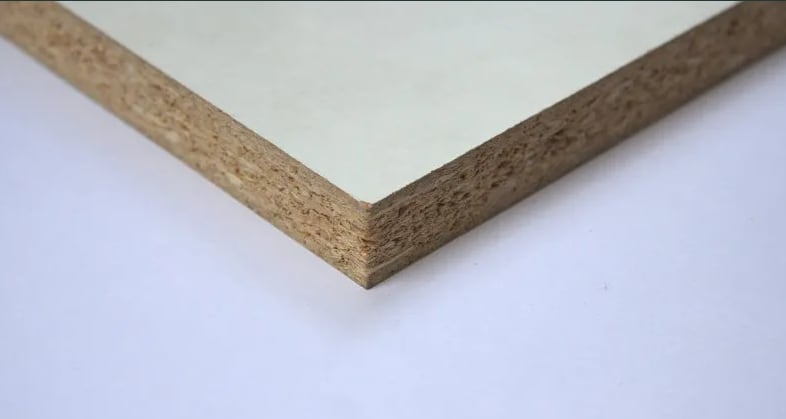

Laminate, melamine (sawdust board)

The laminate contains pulverized wood particles, which are pressed together with various cohesive substances into one large board. In this case, the quality of the board is indicated by the density of particles in the board.

So, anyway: the denser the board, the higher the quality and, unfortunately, the more expensive it is. If you take cheap furniture as an example, then:

- the density of this board in the middle of the board is non-existent, i.e. the board is finger-pinched in the middle

- furniture made of it will not last very long, since the board is simply weak.

However, if we take the board for the manufacture of furniture where the density of the board is uniform and dense through the entire board, then we get one relatively good and durable board as a result.

Sawdust board, as a rule, is covered with various plastic decor or wood veneer. Its screw / fastener holding ability is mediocre.

Two materials are distinguished: melamine and laminate board. The difference lies in the thickness of the decor, or coating.

This material we use for kitchen drawer bottoms and sometimes high-pressure laminate board – for worktops.

MDF board

The main feature of MDF is that it is a medium density fiberboard extruded from wood residues.

Since this board is a moisture-sensitive material, it is a material of high stability. The damp resistance of the MDF board can be increased by using various decors (plastic film, wood veneer) or a corresponding finish.

However, it is worth keeping in mind that if moisture gets into the interior of the board, the result will be spoiled, so either the damaged part or even the entire furniture may need to be replaced.

As the MDF board always stays straight, it is an excellent material for doors and front panels. At the same time, its ability to hold an inside screw or fastener is weak, so it is not suitable for the manufacture of housings.

We rarely use this material, mainly for the manufacture of smooth doors.

Plywood

Plywood is a material obtained by gluing together layers of wood veneer in different directions. The thicker the plywood, the more layers there will be. This, in turn, means that the more layers there are, the more stable it is.

There is a pretty widespread perception that plywood is not very suitable for use in furniture. For example, it is heard quite often that plywood gets crooked and its top layers crack.

In fact, however, the story is that if plywood is used in the furniture body, no matter what room you put that furniture in, you will get one long-lasting and durable piece of furniture.

So durable that its lifespan cannot be predicted. In my 20 years of experience, we have not yet encountered any plywood boards that have cracked on top or somehow warped in the finished furniture.

Another big plus is that, unlike sawdust board or MDF board, plywood furniture can be repaired.

This material we use in the manufacture of furniture

Blockboard

The blockboard is one of the joinery materials with a very long history. As its production was easy and the result is stable, the production of wooden furniture from joinery has been used for a long time.

The blockboard consists of three or more layers. The middle part (the thickest part) is an adhesive board made of an inexpensive type of wood (pine, wood of various palm trees, etc.), which is sanded and covered with veneer or layers on both sides.

In the case of a 5-layer blockboard with a thickness of 18 mm, there is coniferous wood in the middle of the board, which is covered on both sides by 2 layers of veneer glued in different directions. In this way, the stability of the board is achieved. Another advantage is the significantly lighter weight than that of the plywood.

We use this material to make furniture.

Glulam

Glued wood is a material obtained by gluing wood lamellas together.

Lamellas are strips that are glued together side by side. Two varieties of glued wood are distinguished.

- Glulam with full-length lamella

- Finger-jointed glulam

Finger-jointed glulam is made of wooden blocks. It means that good quality wood is glued end-to-the-end, and this is how a lamella is formed. The result is variegated.

Full-length laminated glulam looks more complete and more beautiful. Depending on the use of wood, a price issue also arises – it is more expensive compared to finger-jointed glulam.

Glulam can be used in the manufacture of furniture cabinets as well as elsewhere. Smooth furniture doors (especially large doors with a door width of more than 300 mm) are not reasonable to be made of glulam, as there is a high risk of the doors bending. Frame doors are used to prevent this.

We use glulam boards in the manufacture of furniture, especially long laminated glulam. In the case of oak, also a particularly wide lamella, which leaves the beauty of the wood more complete.